(Posted from China Injection Mold blog)

Check out these injection molds factory images:

Plastics Injection Factory

Image by ReneePrisble

Read more about Nice Injection Molds Factory photos

(Posted from China Injection Mold blog)

Check out these injection molds factory images:

Plastics Injection Factory

Image by ReneePrisble

(Posted from China Injection Mold blog)

A few nice mould manufacturing factory images I found:

1910 Chase Model D Truck

Image by pecooper98362

Guaranteed by the manufacturer to be free of all defects for 1 year

Engine: Air-cooled; 2 cycle – 3 cylinder, 20 hp

Factory Price: ,000; manufactured in Syracuse, NY

This truck started its life as a fire truck in Almond, NY. However, its career was short-lived when the village experienced a bad fire and it fails to start. The village fathers went back to their horse-drawn pumper, and used it until 1920 when they purchased a Brockway.

In 1924, the truck was purchased as a 1905 model for 50 cents at a local auction. In the 30s and 40s it was used for paraded. The current owner acquired it the truck in 1960 and began a 30-year restoration, with his first research revealing that it was actually a 1910. The first 16 years of restoration were spent trying to find tires, and he almost gave up,but in 1976, an ad in Hemmings solved the problem. Using original manuals, an ash body was built to the exact dimensions as it would have come from the factory in 1910; new pistons were cast from a mold made from the only good piston left in the truck. Piece by piece, the restoration progressed and finally, in 1994, the truck was finished as you see it today.

Image from page 158 of “India rubber world” (1899)

Image by Internet Archive Book Images

Identifier: indiarubberworld49phil

Title: India rubber world

Year: 1899 (1890s)

Authors:

Subjects: Rubber industry and trade

Publisher: [Philadelphia, Bill Brothers Publishing Corp.]

Contributing Library: The LuEsther T Mertz Library, the New York Botanical Garden

Digitizing Sponsor: The LuEsther T Mertz Library, the New York Botanical Garden

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

ky, with a capital of ,000 for the manufacture ofa patented automobile wheel. The principal incorporators areG. A. Simpson, of Ludlow, and Charles Schroeder, of Cincinnati.Ohio. Mahlow & Wyckhoff, manufacturers of hard rubber negativesand soft rubber molds, have recently removed from 325 SouthWarren street, Trenton, New Jersey, to Brunswick avenue, andEast Trenton Railroad, in the same city. The Thermoid 100 per cent. Perfect Brake Lining, made bytlie Thermoid Rubber Co., of Trenton, New Jersey, is now usedby twenty-six of the popular motor cars of the United Statesand Europe. THE HARTFORD RUBBER PLANTATION. Many ruljlier manufacturers here and abroad own rubber plan-tations situated somewhere in the tropics. It remains, however,for the Hartford Rubber Works to install their own idantationright in the factory. In the warm, light boiler room there aregrowing today healthy specimens of the Heiea Brasiliensis, Cas-lilliHi Elastica. and the ficus l-.hstica. So far, these trees have

Text Appearing After Image:

Rubber Plant.^tion of the Hartford Rubber Works Co. not been tapped, and will not be until a new tapping device pro-jected by Mr. Whittlesey is completed. Confidentially, the device is to be a cutting-knife attached to avacuum extractor which will draw the latex as far as the millroom, coagulate it over the mixing mills, and automatically feedit into the rolls for massing. Should be on every rubber mans desk—Crude Rubber andCompounding Ingredients: Rubber Country of the Amazon;Ruliber Trade Directorv of the World. 142 THE INDIA RUBBER WORLD [December 1, 1913. A CUSHION TIRE FOR MOTOR TRUCKS. AFTER considerable experimenting on the part of the manu-facturers, a solid rubber cushion truck tire has been pro-duced with the intention of meeting the adverse conditionsunder which motor trucks are operated. This same type of tirehas been used on electric pleasure cars for several years past, and

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

(Posted from China Injection Mold blog)

Some cool mould produce maker images:

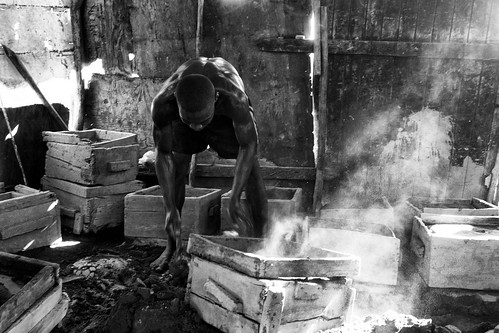

Making of Aluminium Cooking Pots in Cité Soleil, Haiti

Image by United Nations Photo

30 years ago Mones Mondasar’s father, established himself as an aluminum cooking pot maker in Port-au-Prince’s Cite Soleil, Haiti’s largest and most infamous slum. Now 45, Mondasar and his 25 year old son Walnes, continue the tradition producing up to 10 pots a week. It’s a small number by modern manufacturing standards, but everything depends on what scrap aluminum can be collected to be melted down and poured into hand made sand molds. The finished product will bring 500 Haitian Gourds each – approximately US – in Port-au-Prince’s central market.

UN Photo/Nektarios Markogiannis

Making of Aluminium Cooking Pots in Cité Soleil, Haiti

Image by United Nations Photo

30 years ago Mones Mondasar’s father, established himself as an aluminum cooking pot maker in Port-au-Prince’s Cite Soleil, Haiti’s largest and most infamous slum. Now 45, Mondasar and his 25 year old son Walnes, continue the tradition producing up to 10 pots a week. It’s a small number by modern manufacturing standards, but everything depends on what scrap aluminum can be collected to be melted down and poured into hand made sand molds. The finished product will bring 500 Haitian Gourds each – approximately US – in Port-au-Prince’s central market.

UN Photo/Nektarios Markogiannis

(Posted from China Injection Mold blog)

Some cool china mold images:

DSC01258

Image by lyng883

Shanghai Moon – is one of those few restaurants whose interior decor alone is worth the trip. And if you go in the middle of the night you can have the place to yourself. It’s open 24-hours a day. From the elevator, follow the thinning red carpet down the hall and into the ballroom-style dining room, where the carpet springs back to life in a swirl of red, blue and cream. Pick one of the mismatched embroidered chairs and sit down to a quintessential Chinese table, a pink carnation in a glass vase and a red tablecloth. See the majestic and old-fashioned surroundings: the antiques, the chandeliers, the grand ceiling with distinctive molding and alcoves with velvet curtains. On the walls, there are photos of Shanghai circa 1840s-1950s showing the everyday landmarks of the era (the first department store, the first cinema, the Huangpu full of canoe-sized boats) as well as landmark events like Prince Chun of the Qing Dynasty’s parade down Nanjing Xi Lu. The menu is full of your standard Shanghainese fare, with a bit of Cantonese influence

(Posted from China Injection Mold blog)

A few nice plastic injection china images I found:

Shenzhen, Oct-2013

Image by maltman23

Visit to Shande Industry Co

who Seeed Studio uses for their plastic injection molding

Shenzhen

October-2013

(Posted from China Injection Mold blog)

A few nice china tooling factory images I found:

delighting “me” always

Image by Shaojin+AT

delighting "me" always

Picture: I suppose to focus my camera on the sculpture instead of on the pink lady. However, I was surprised when I got home with this result, my camera chosen to focus on pink lady! It is delighting me!!!

Canon, delighting you always…

Location: 798 Art Zone, Beijing. China

798 Art Zone (Chinese: 798艺术区; pinyin: 798 Yìshùqū), or Dashanzi Art District, is a part of Dashanzi in the Chaoyang District of Beijing that houses a thriving artistic community, among 50-year old decommissioned military factory buildings of unique architectural style. It is often compared with New York’s Greenwich Village or SoHo.

The area is often called the 798 Art District or Factory 798 although technically, Factory #798 is only one of several structures within a complex formerly known as Joint Factory 718. The buildings are located inside alleys number 2 and 4 on Jiǔxiānqiáo Lù (酒仙桥路), south of the Dàshānziqiáo flyover (大山子桥).

Construction

798 Space gallery, Jan,2009. Old Maoist slogans are visible on the ceiling arches.

The Dashanzi factory complex began as an extension of the "Socialist Unification Plan" of military-industrial cooperation between the Soviet Union and the newly formed People’s Republic of China. By 1951, 156 "joint factory" projects had been realized under that agreement, part of the Chinese government’s first Five-Year Plan. However the People’s Liberation Army still had a dire need of modern electronic components, which were produced in only two of the joint factories. The Russians were unwilling to undertake an additional project at the time, and suggested that the Chinese turn to East Germany from which much of the Soviet Union’s electronics equipment was imported. So at the request of then-Premier Zhou Enlai, scientists and engineers joined the first Chinese trade delegation to East Germany in 1951, visiting a dozen factories. The project was greenlighted in early 1952 and a Chinese preparatory group was sent to East Berlin to prepare design plans. This project, which was to be the largest by East Germany in China, was then informally known as Project #157.

The architectural plans were left to the Germans, who chose a functional Bauhaus-influenced design over the more ornamental Soviet style, triggering the first of many disputes between the German and Russian consultants on the project. The plans, where form follows function, called for large indoor spaces designed to let the maximum amount of natural light into the workplace. Arch-supported sections of the ceiling would curve upwards then fall diagonally along the high slanted banks or windows; this pattern would be repeated several times in the larger rooms, giving the roof its characteristic sawtooth-like appearance. Despite Beijing’s northern location, the windows were all to face north because the light from that direction would cast fewer shadows.

The chosen location was a 640,000 square metres area in Dashanzi, then a low-lying patch of farmland northeast of Beijing. The complex was to occupy 500,000 square metres, 370,000 of which were allocated to living quarters. It was officially named Joint Factory 718, following the Chinese government’s method of naming military factories starting with the number 7. Fully funded by the Chinese side, the initial budget was enormous for the times: 9 million rubles or approximately 140 million RMB (US million) at today’s rates; actual costs were 147 million RMB.

Ground was broken in April 1954. Construction was marked by disagreements between the Chinese, Soviet and German experts, which led at one point to a six-month postponement of the project. The Germans’ harshest critic was the Russian technology consultant in charge of Beijing’s two Soviet-built electronics factories (714 and 738), who was also head consultant of the Radio Industrial Office of the Second Ministry of Machine Building Industry. The disputes generally revolved around the Germans’ high but expensive quality standards for buildings and machines, which were called "over-engineering" by the Russians. Among such points of contention was the Germans’ insistence, historical seismic data in hand, that the buildings be built to withstand earthquakes of magnitude 8 on the Richter scale, whereas the Chinese and Russians wanted to settle for 7. Communications expert Wang Zheng, head of Communications Industry in the Chinese Ministry of National Defense and supporter the East German bid from the start, ruled in favor of the Germans for this particular factory.

At the height of the construction effort, more than 100 East German foreign experts worked on the project. The resources of as many as 22 of their factories supplied the construction; at the same time, supply delays were caused by the Soviet Red Army’s tremendous drain on East Germany’s industrial production. The equipment was transported directly through the Soviet Union via the Trans-Siberian railway, and a 15 km track of railroad between Beijing Railway Station and Dongjiao Station was built especially to service the factory. Caltech-educated scientist Dr. Luo Peilin (罗沛霖), formerly head of the preparatory group in 1951-1953, was Head Engineer of Joint Factory 718 during its construction phase. Dr. Luo, now retired in Beijing, is remembered by his former colleagues as a dedicated perfectionist whose commitment to the obstacle-strewn project was a major factor of its eventual success.

[edit]Operation

Joint Factory 718 began production in 1957, amid a grandiose opening ceremony and display of Communist brotherhood between China and East Germany, attended by high officials of both countries. The first director was Li Rui (李瑞), who had been involved in the early negotiations in Berlin.

The factory quickly established a reputation for itself as one of the best in China. Through its several danwei or "work units", it offered considerable social benefits to its 10,000-20,000 workers, especially considering the relative poverty of the country during such periods as the Great Leap Forward. The factory boasted, among others:

the best housing available to workers in Beijing, providing fully furnished rooms to whole families for less than 1/30 of the workers’ income;

diverse extracurricular activities such as social and sporting events, dancing, swimming, and training classes;

its own athletics, soccer, basketball and volleyball teams for men and women, ranked among the best in inter-factory competitions;

a brigade of German-made motorcycles, performing races and stunt demonstrations;

an orchestra that played not only revolutionary hymns, but also German-influenced classical Western music;

literary clubs and publications, and a library furnished with Chinese and foreign (German) books;

Jiuxianqiao hospital, featuring German equipment and offering the most advanced dental facilities in China.

The factory even had its own volunteer military reserves or jinweishi (近卫师), which numbered hundreds and were equipped with large-scale weapons and anti-aircraft guns.

Workers’ skills were honed by frequent personnel exchanges, internships and training in cooperation with East Germany. Different incentives kept motivation high, such as rewards systems and "model worker" distinctions. At the same time, political activities such as Maoism study workshops kept the workers in line with Communist Party of China doctrine. During the Cultural revolution, propaganda slogans for Mao Zedong Thought were painted on the ceiling arches in bright red characters (where they remain today at the latter tenants’ request).

Frequent VIP visits contributed to the festive atmosphere. Notable guests included Deng Xiaoping, Jiang Zemin, Liu Shaoqi, Zhu De, and Kim Il-Sung.

The Joint Factory produced a wide variety of military and civilian equipment. Civilian production included acoustic equipment for Beijing’s Workers’ Stadium and Great Hall of the People, as well as all the loudspeakers on Tiananmen Square and Chang’an Avenue. Military components were also exported to China’s Communist allies, and helped establish North Korea’s wireless electronics industry.

One of the old machine tools in front of some contemporary art in Dec 2005

After 10 years of operation, Joint Factory 718 was split into more manageable components, such as sub-Factories 706, 707, 751, 761, 797 and 798. The first Head of sub-Factory 798 (the largest) was Branch Party Secretary Fu Ke (傅克), who played a major role in recruiting skilled workers from southern China and among returned overseas Chinese.

However, the factory came under pressure during Deng Xiaoping’s reforms of the 1980s. Deprived of governmental support like many state-owned enterprises, it underwent a gradual decline and was eventually rendered obsolete. By the late 1980s and early 1990s, most sub-factories had ceased production, 60% of the workers had been laid off, and the remains of the management were reconstituted as a real-estate operation called "Seven-Star Huadian Science and Technology Group", charged with overseeing the industrial park and finding tenants for the abandoned buildings.

[edit]

The Dashanzi factory complex was vacated at around the time when most of Beijing’s contemporary artist community was looking for a new home. Avant-garde art being frowned upon by the government, the community had traditionally existed on the fringes of the city. From 1984 to 1993, they worked in run-down houses near the Old Summer Palace (Yuanmingyuan) in northwestern Beijing, until their eviction. They had then moved to the eastern Tongxian County (now Tongzhou District), more than an hour’s drive from the city center.

Then in 1995, Beijing’s Central Academy of Fine Arts (CAFA), looking for cheap, ample workshop space away from downtown, set up in the now defunct Factory 706. The temporary move became permanent and in 2000 Sui Jianguo(隋建国), Dean of the Department of Sculpture, located his own studio in the area. The cluttered sculpture workshops have always remained open for visitors to peek at the dozens of workers milling about.

In 2001, Texan Robert Bernell moved his Timezone 8 Art Books bookshop and publishing office (founded in 1997) into a former factory canteen; he was the first foreigner to move in. One of Timezone 8’s early employees was fashion designer Xiao Li, who along her husband, performance artist Cang Xin, helped artists secure and rent spaces in the area.

Through word-of-mouth, artists and designers started trickling in, attracted to the vast cathedral-like spaces. Despite the lack of any conscious aesthetic in the Bauhaus-inspired style, which grounded architectural beauty in practical, industrial function, the swooping arcs and soaring chimneys had an uplifting effect on modern eyes, a sort of post-industrial chic. At the artists’ requests, workers renovating the spaces preserved the prominent Maoist slogans on the arches, adding a touch of ironic "Mao kitsch" to the place.

Later that year, Mr. Tabata Yukihito from Japan’s Tokyo Gallery set up Beijing Tokyo Art Projects (BTAP, 北京东京艺术工程) inside a 400-m² division of Factory 798’s main area; this was the first renovated space featuring the high arched ceilings that would become synonymous with the Art District. BTAP’s 2002 opening exhibition "Beijing Afloat" (curator: Feng Boyi), drew a crowd of over 1,000 people and marked the beginning of the popular infatuation with the area.

In 2002, designer artist Huang Rui (黄锐) and hutong photographer Xu Yong (徐勇) set up the 798 Space gallery (时态空间) next to BTAP. With its cavernous 1200-m² floor and multiple-arched ceilings at the center of Factory 798, it was and still is the symbolic center of the whole district. (Huang and Xu since designed at least seven spaces in the area and became the prime movers and de facto spokespersons of the District.) A glass-fronted café was set up in the former office section at the back of the 798 space, opening into a back alley now lined with studios and restaurants such as Huang’s own At Café, and Cang Xin’s #6 Sichuan restaurant, the area’s "canteen".

In 2003, Lu Jie (卢杰) set up the Long March Foundation, an ongoing project for artistic re-interpretation of the historical Long March, inside the 25,000 Li Cultural Transmission Center (二万五千里文化传播中心). Around that time, Singapore-owned China Art Seasons (北京季节画廊) opened for display for pan-Asian art, and was one of several new galleries setting up at that time.

Source from: en.wikipedia.org/wiki/798_Art_Zone

(Posted from China Injection Mold blog)

Check out these plastic moulding china images:

Shenzhen, Oct-2017

Image by maltman23

A few things they make

at AMC (plastic injection molding factory)

4th of 4 factories

on the day of factory tours

Shenzhen

October-2017

Shenzhen, Oct-2017

Image by maltman23

Anti-smoking poster

at AMC (plastic injection molding factory)

4th of 4 factories

on the day of factory tours

Shenzhen

October-2017

Shenzhen, Oct-2017

Image by maltman23

AMC (plastic injection molding factory)

4th of 4 factories

on the day of factory tours

Shenzhen

October-2017

(Posted from China Injection Mold blog)

Check out these plastic model airplanes images:

Concorde!

Image by Chris Devers

Posted via email to ☛ HoloChromaCinePhotoRamaScope‽: cdevers.posterous.com/concorde. See the full gallery on Posterous …

• • • • •

Quoting Smithsonian National Air and Space Museum | Concorde, Fox Alpha, Air France:

The first supersonic airliner to enter service, the Concorde flew thousands of passengers across the Atlantic at twice the speed of sound for over 25 years. Designed and built by Aérospatiale of France and the British Aviation Corporation, the graceful Concorde was a stunning technological achievement that could not overcome serious economic problems.

In 1976 Air France and British Airways jointly inaugurated Concorde service to destinations around the globe. Carrying up to 100 passengers in great comfort, the Concorde catered to first class passengers for whom speed was critical. It could cross the Atlantic in fewer than four hours – half the time of a conventional jet airliner. However its high operating costs resulted in very high fares that limited the number of passengers who could afford to fly it. These problems and a shrinking market eventually forced the reduction of service until all Concordes were retired in 2003.

In 1989, Air France signed a letter of agreement to donate a Concorde to the National Air and Space Museum upon the aircraft’s retirement. On June 12, 2003, Air France honored that agreement, donating Concorde F-BVFA to the Museum upon the completion of its last flight. This aircraft was the first Air France Concorde to open service to Rio de Janeiro, Washington, D.C., and New York and had flown 17,824 hours.

Gift of Air France.

Manufacturer:

Societe Nationale Industrielle Aerospatiale

British Aircraft Corporation

Dimensions:

Wingspan: 25.56 m (83 ft 10 in)

Length: 61.66 m (202 ft 3 in)

Height: 11.3 m (37 ft 1 in)

Weight, empty: 79,265 kg (174,750 lb)

Weight, gross: 181,435 kg (400,000 lb)

Top speed: 2,179 km/h (1350 mph)

Engine: Four Rolls-Royce/SNECMA Olympus 593 Mk 602, 17,259 kg (38,050 lb) thrust each

Manufacturer: Société Nationale Industrielle Aérospatiale, Paris, France, and British Aircraft Corporation, London, United Kingdom

Physical Description:

Aircaft Serial Number: 205. Including four (4) engines, bearing respectively the serial number: CBE066, CBE062, CBE086 and CBE085.

Also included, aircraft plaque: "AIR FRANCE Lorsque viendra le jour d’exposer Concorde dans un musee, la Smithsonian Institution a dores et deja choisi, pour le Musee de l’Air et de l’Espace de Washington, un appariel portant le couleurs d’Air France."

Airfix 1/72 Helldiver

Image by migrant_60

Built for ‘Airfix Mdel World’ magazine. I would probably have achieved a better and more accurate result with the Academy kit, but I must admit I enjoyed building this old 60s beast.