(Posted from China Injection Mold blog)

A few nice mould manufacturing factory images I found:

1910 Chase Model D Truck

Image by pecooper98362

Guaranteed by the manufacturer to be free of all defects for 1 year

Engine: Air-cooled; 2 cycle – 3 cylinder, 20 hp

Factory Price: ,000; manufactured in Syracuse, NY

This truck started its life as a fire truck in Almond, NY. However, its career was short-lived when the village experienced a bad fire and it fails to start. The village fathers went back to their horse-drawn pumper, and used it until 1920 when they purchased a Brockway.

In 1924, the truck was purchased as a 1905 model for 50 cents at a local auction. In the 30s and 40s it was used for paraded. The current owner acquired it the truck in 1960 and began a 30-year restoration, with his first research revealing that it was actually a 1910. The first 16 years of restoration were spent trying to find tires, and he almost gave up,but in 1976, an ad in Hemmings solved the problem. Using original manuals, an ash body was built to the exact dimensions as it would have come from the factory in 1910; new pistons were cast from a mold made from the only good piston left in the truck. Piece by piece, the restoration progressed and finally, in 1994, the truck was finished as you see it today.

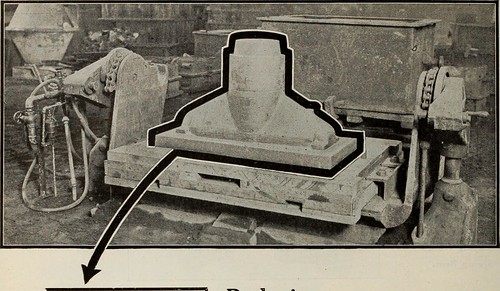

Image from page 158 of “India rubber world” (1899)

Image by Internet Archive Book Images

Identifier: indiarubberworld49phil

Title: India rubber world

Year: 1899 (1890s)

Authors:

Subjects: Rubber industry and trade

Publisher: [Philadelphia, Bill Brothers Publishing Corp.]

Contributing Library: The LuEsther T Mertz Library, the New York Botanical Garden

Digitizing Sponsor: The LuEsther T Mertz Library, the New York Botanical Garden

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

ky, with a capital of ,000 for the manufacture ofa patented automobile wheel. The principal incorporators areG. A. Simpson, of Ludlow, and Charles Schroeder, of Cincinnati.Ohio. Mahlow & Wyckhoff, manufacturers of hard rubber negativesand soft rubber molds, have recently removed from 325 SouthWarren street, Trenton, New Jersey, to Brunswick avenue, andEast Trenton Railroad, in the same city. The Thermoid 100 per cent. Perfect Brake Lining, made bytlie Thermoid Rubber Co., of Trenton, New Jersey, is now usedby twenty-six of the popular motor cars of the United Statesand Europe. THE HARTFORD RUBBER PLANTATION. Many ruljlier manufacturers here and abroad own rubber plan-tations situated somewhere in the tropics. It remains, however,for the Hartford Rubber Works to install their own idantationright in the factory. In the warm, light boiler room there aregrowing today healthy specimens of the Heiea Brasiliensis, Cas-lilliHi Elastica. and the ficus l-.hstica. So far, these trees have

Text Appearing After Image:

Rubber Plant.^tion of the Hartford Rubber Works Co. not been tapped, and will not be until a new tapping device pro-jected by Mr. Whittlesey is completed. Confidentially, the device is to be a cutting-knife attached to avacuum extractor which will draw the latex as far as the millroom, coagulate it over the mixing mills, and automatically feedit into the rolls for massing. Should be on every rubber mans desk—Crude Rubber andCompounding Ingredients: Rubber Country of the Amazon;Ruliber Trade Directorv of the World. 142 THE INDIA RUBBER WORLD [December 1, 1913. A CUSHION TIRE FOR MOTOR TRUCKS. AFTER considerable experimenting on the part of the manu-facturers, a solid rubber cushion truck tire has been pro-duced with the intention of meeting the adverse conditionsunder which motor trucks are operated. This same type of tirehas been used on electric pleasure cars for several years past, and

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

Read more about Cool Mould Manufacturing Factory images