(Posted from China Injection Mold blog)

Some cool mould manufacturing factory images:

Image from page 47 of “Rubber hand stamps and the manipulation of rubber; a practical treatise on the manufacture of India rubber hand stamps, small articles of India rubber, the hektograph, special inks, cements, and allied subjects” (1891)

Image by Internet Archive Book Images

Identifier: rubberhandstamps01sloa

Title: Rubber hand stamps and the manipulation of rubber; a practical treatise on the manufacture of India rubber hand stamps, small articles of India rubber, the hektograph, special inks, cements, and allied subjects

Year: 1891 (1890s)

Authors: Sloane, T. O’Conor (Thomas O’Conor), 1851-1940

Subjects: Hand stamps Rubber

Publisher: New York, N. W. Henley & Co.

Contributing Library: The Library of Congress

Digitizing Sponsor: Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

anized product. Sheet rubber is made as above;is vulcanized by some of the absorption processesdescribed in the chapter on vulcaniza-tion. We now come to the second product: regularlymixed and cured rubber. Its starting point isthe washed India rubber from the washer andsheeter. We have seen that the ^^ure gum or caoutchouc isvery sensitive to changes of temperature. At thefreezing point of water it is hard and rigid, and at 42 RUBBER HAND STAMP MAKING the boiling point is like putty in consistency.There are several substances wliich can be made tocombine with the gum and which remove from itthis susceptibility to change of temperature. Theprocess of effecting this combination is called vul-canization, and the product is called vulcanizedindia rubber. Sulphur is the agent most generallyemployed. In the factory the normal vulcanization is carriedout in two steps, mixing and curing. The washedsheet india rubber which has not been masticatedand which must be perfectly dry is the starting

Text Appearing After Image:

Making i^Iixed Ritbber. point, andtlie mixing rolls sliown in the cuts are themechanism for carrying out the first step. Theseare a pair of powerful rollers which are geared so asto work like ordinary rolls, except that one revolves AND THE MANIPULATION OF RUBBER. 43 about three times as fast as the other. They areheated by steam, which is introduced inside ofthem. The sheet is first passed through them afew times to secure its softness, and then the opera-tive begins to sprinkle sulphur upon it as it entersthe rolls. This is continued, the rubber passing andrepassing until perfect incorporation is secured.About ten per cent, of sulphur is added, and a work-man can take care of thirty pounds at a time. This material is incompletely vulcanized. It isin its present condition very amenable to heat andis ready for any moulding process. Generally it isrolled out or ^^ calendered into sheets of differentthickness from which articles are made in mouldsby curing. These sheets are of especial

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

Image from page 413 of “Canadian foundryman (1921)” (1921)

Image by Internet Archive Book Images

Identifier: canfoundryman1921toro

Title: Canadian foundryman (1921)

Year: 1921 (1920s)

Authors:

Subjects: Foundries Foundry workers

Publisher: Toronto : MacLean Pub. Co

Contributing Library: Fisher – University of Toronto

Digitizing Sponsor: University of Toronto

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

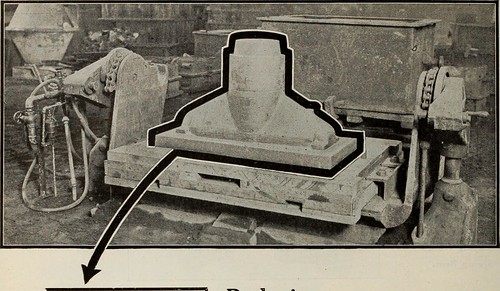

supplies.Our lines com-prise the highestgrade equipmentobtainable any-where. You Cant Afford to Overlook theseMoney Saving Opportunities We are offering you at prices beyond comparison the high-est grade Foundry Equipment obtainable anywhere. If youare wide awake for real values investigate these lines. Get Our Prices on Ladle Bowls and Shanks.Steel Bands Steel Slip-over Jackets.Steel Core Plates.Wooden Snap Flasks. Youll find longer servicein our flat bottom steelladle bowls. These bowlscome in capacities from 50to 800 lbs. Dont shove this oppor-tunity aside. Write atonce for Prices and liberalDiscounts. All Steel Core Ovens Thes* core ovens have nocast parts to break. Extrasmoke pipe connection takesexcess smoke away. Alldoors have Battle Plate toreduce heat loss when door isopen. pAMP pROS Tote Box, Barrels, etc.All-Steel Core Ovens. Manufacturing and Welding Co. We can supply AluminumPattern Plates in any size. 825 DUPONT STREET, TORONTO, ONTARIO 26 CANADIAN FOUNDRYMAN Volume XII

Text Appearing After Image:

Heres the history of this jobin a jobbing foundry beforeand after machine-moulding:- Weight, 275 pounds.Flask (inside). 42 x 33 x 24 high. Before Mounting—One man put up4 moulds in 7 hours After Mounting— 4 men and one No. machine put up 45 moulds in 7 hours. 435 Labor Required For moulding, coring, closingand pouring each moudBefore—2V* man-hours.After—8-10ths man-hrs. Cost of Mounting Pattern,including labor andmaterials, .00. Labor Cost reduced 62 M: /<. Cost of Pattern Mounting saved on the first 28moulds. Reducing costs to meet1921 requirements J7CONOMY in productionis the keynote of 1921 man-ufacturing and selling prob-lems. Extravagant produc-tion costs can no longer bepassed on to a helpless con-sumer. Machine-molding must be util-ized wherever possible in orderthat selling prices will seemreasonable to buyers.The Osborn Manufacturing Company INCORPORATED Main Office and Factory 5401 Hamilton Ave. Cleveland, Ohio New York San Francisco

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

Read more about Cool Mould Manufacturing Factory images

No comments:

Post a Comment